Belt replacement is a crucial aspect of maintaining the efficiency and longevity of various types of machinery, from automobiles to industrial equipment. At its core, belt replacement involves swapping out worn or damaged belts for new ones, ensuring that the machines continue to operate smoothly and effectively. The importance of timely belt replacement cannot be overstated, as neglected belts can lead to reduced performance, unexpected breakdowns, and potentially costly repairs. Understanding the basics of belt replacement is the first step in maintaining machinery that performs at optimal levels.

Different types of belts, such as serpentine belts, V-belts, and timing belts, play pivotal roles in mechanical operations. Each type serves specific functions and is suited for distinct applications, highlighting the need for accurate identification and understanding to ensure a successful replacement. Recognizing when a belt needs replacing is essential for proactive maintenance. Common symptoms such as fraying, cracking, or a noticeable loss of tension can signal the need for a new belt. Being alert to these signs can prevent more significant issues down the line.

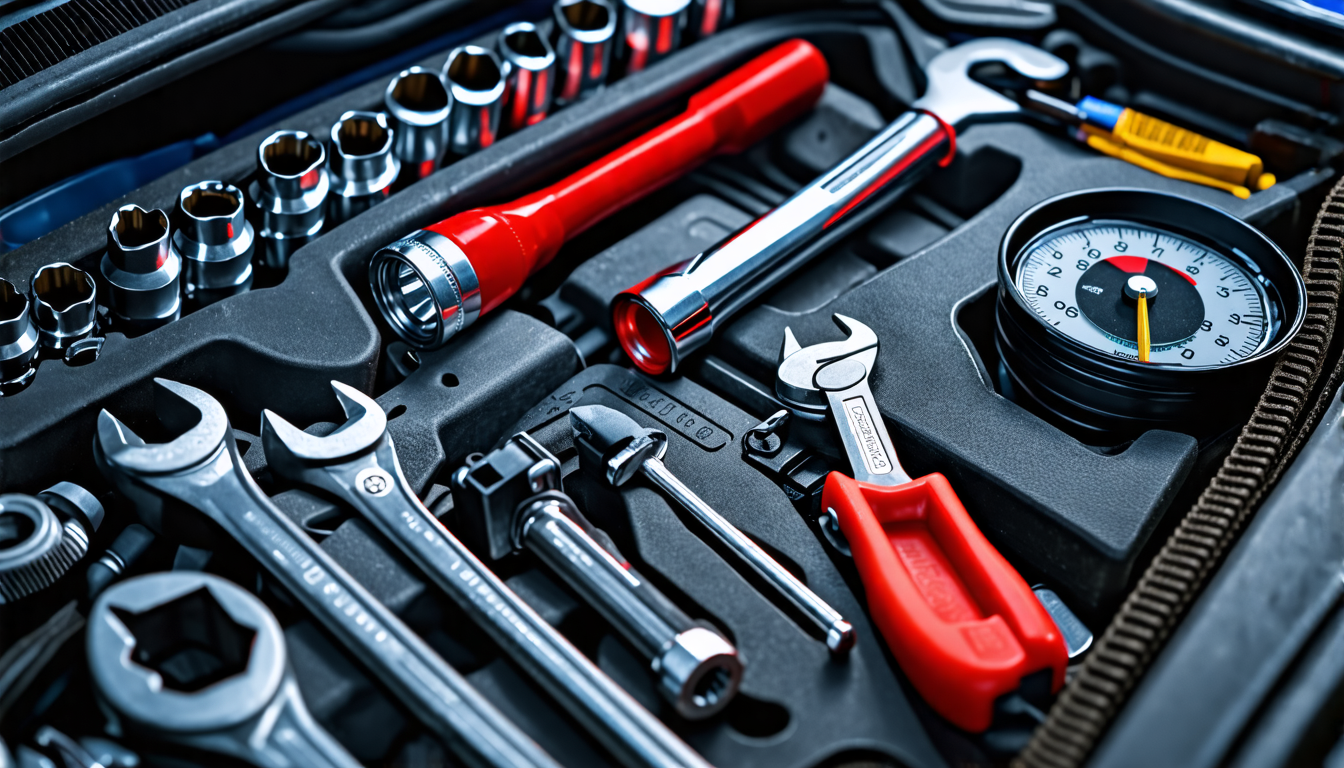

For a smooth belt replacement process, proper preparation and understanding of the tools required are critical. Equipping oneself with the right knowledge and equipment can help avoid common pitfalls associated with belt replacement. Furthermore, following a detailed step-by-step guide is invaluable, as it walks the installer through the entire process, from removal to installation, ensuring no step is overlooked. Safety is paramount; adhering to essential safety tips helps protect both the installer and the machinery during the replacement process.

Expert tips and tricks can significantly enhance the efficiency of belt replacement. One of the main challenges is avoiding common mistakes, which can often lead to additional problems or reduced belt life. By following preventive strategies, these errors can be minimized. Post-replacement maintenance is also crucial; regular checks and proper care will extend the lifespan of new belts, ensuring machinery continues to function properly. Additionally, the ability to troubleshoot any post-replacement issues, such as unusual noises or improper tension, ensures that any unexpected incidents are swiftly and effectively addressed. Following these guidelines and insights not only makes the belt replacement process smoother but also elevates the overall performance and durability of the machinery involved.

Understanding Belt Replacement Basics

Introduction to Belt Replacement

Belt replacement is a critical aspect of machinery maintenance that ensures the longevity and optimal performance of equipment. At its core, belt replacement involves removing a worn or damaged belt from a device and installing a new one. This practice is vital because belts play a crucial role in the operation of various mechanical systems, transmitting power between different components. When a belt wears out, it can lead to inefficient machinery operation, increased energy consumption, and potential equipment failure. Regular belt replacement not only prevents these issues but also enhances the efficiency and productivity of machines like automobiles, lawnmowers, and industrial equipment.

Types of Belts

Several types of belts are used in machinery, each designed for specific applications. Understanding these types is essential for selecting the right belt for replacement:

- Serpentine Belts: Serpentine belts are commonly used in automotive engines to drive multiple peripheral devices such as the alternator, power steering pump, and air conditioning compressor. These belts are known for their durability and flexibility, allowing them to navigate through various pulleys efficiently.

- V-belts: V-belts are widely used in industrial settings, characterized by their V-shaped cross-sections. They are designed to fit into V-shaped pulley grooves, which increases the frictional force and power transfer efficiency. V-belts are suitable for high-speed and high-power applications.

- Timing Belts: Timing belts are integral in synchronizing the movement of engine components, such as the camshaft and crankshaft, in automotive engines. They are made of rubber with teeth on the inside surface to engage with a cogwheel. Accurate timing is essential to prevent engine damage, making regular inspection and replacement of timing belts crucial.

Signs You Need a Belt Replacement

Identifying the signs that a belt needs replacement can prevent unexpected equipment failure and costly repairs. Here are some common indicators that it’s time to consider belt replacement:

- Squealing or Whining Noise: Unusual noises coming from the belt area can indicate belt wear, misalignment, or slippage. Such sounds are typically caused by friction between the belt and pulleys, suggesting it’s time for an inspection.

- Visible Cracks or Wear: Regularly inspect belts for visible signs of wear, such as cracks, fraying, or glazing. These signs suggest the belt is deteriorating and may soon fail.

- Loss of Tension: A belt that feels loose and lacks proper tension can lead to inefficient power transmission. Tension loss is often due to wear or incorrect installation, necessitating replacement or adjustment.

- Overheating: If machinery components are overheating, this could be a consequence of a worn belt struggling to maintain power efficiency. Overheating can indicate belt slippage or improper tension, which needs immediate attention.

- Reduced Performance: A decline in machine performance, such as reduced speed or efficiency, may result from an old or damaged belt that can no longer transmit power effectively.

By understanding the fundamentals of belt replacement, types of belts, and recognizing symptoms of wear, you can maintain the efficiency and reliability of your machinery. Timely belt replacement not only ensures continuous operation but also reduces downtime and maintenance costs, keeping your equipment in top shape.

Preparation and Tools Needed

Before diving into the belt replacement process, proper preparation is crucial for ensuring a smooth and efficient installation. A successful belt replacement starts with having the right tools and knowledge on hand. First, ensure you have a reliable set of wrenches, sockets, and screwdrivers, as these are fundamental for removing and installing components. Depending on the machinery, specialty tools like a serpentine belt tool or a tension gauge may be required to correctly adjust the belt tension. It is also wise to secure a reliable belt tensioner tool to prevent over-tightening, which can cause premature wear and tear on the new belt.

Make sure to carefully review the owner’s manual for your specific machinery, as it will provide valuable insights into the exact specifications and requirements of your belt replacement. This preparation will not only save you time but also help you avoid common pitfalls such as lack of access to chain guards or tensioning mechanisms, which can complicate the process. Additionally, have a clean workspace ready, preferably with good lighting, to minimize errors and misplacements during the replacement process.

Detailed Installation Process

Now that you’ve gathered your tools and set up your workspace, it’s time to delve into the installation process itself. Follow this comprehensive step-by-step guide to ensure a seamless belt replacement:

- Disconnect the Power: Ensure the machine is switched off and unplugged from the power source to prevent any accidental startups.

- Remove the Old Belt: Begin by locating the belt tensioner and relieve tension on the belt by using the appropriate tool. Carefully slide the old belt off the pulleys, noting their configuration for an accurate reinstallation.

- Inspect Components: Check the condition of pulleys, tensioners, and other adjacent components for wear and damage. It’s advisable to replace these parts simultaneously if they’re significantly worn to avoid future issues.

- Install the New Belt: Position the new belt on the pulleys according to the correct configuration. Ensure it is aligned properly to prevent misalignment issues that could lead to premature belt failure.

- Adjust Tension: Utilize a belt tension gauge to adjust the tension according to the manufacturer’s recommendation. Proper tension is crucial to the longevity and efficiency of the belt.

- Double-Check Alignment and Tension: Re-examine the pulleys and belt for proper alignment and tension. A misaligned belt can cause squealing noises or escape the pulleys during operation.

- Reassemble and Test: Once everything is in place, reassemble any removed parts and plug the machine in to test its operation. Listen for unusual noises and observe for irregular operation, which could indicate an incorrect installation.

Safety Tips During Belt Replacement

Safety should be your top priority when performing a belt replacement. Not only does it ensure your protection, but it also helps in avoiding any accidental damage to the machinery. Here are some crucial safety tips:

- Wear Personal Protective Equipment: Always wear eye protection, gloves, and work boots to safeguard against any accidental injuries.

- Secure the Area: Make sure the workspace is clear of any unnecessary items and keep a clear perimeter to avoid tripping hazards.

- Avoid Loose Clothing and Hair: Loose clothing or long hair can easily become entangled in moving parts. Ensure these elements are secured away from potential hazards.

- Be Cautious with Tools: Use tools correctly and ensure they are in good working order. Damaged tools can slip, causing injury or improper installation.

- Handle Components Carefully: Pulleys and belts can be heavy and cumbersome. Use proper lifting techniques to avoid strain or injury.

By following these steps and precautions, you can carry out a belt replacement efficiently and safely, ensuring your machinery operates smoothly and effectively.

Common Mistakes to Avoid

During belt replacement, enthusiasts and professionals alike can encounter various hurdles that hinder efficiency and longevity. One prevalent misstep is ignoring the manufacturer’s specifications. Each belt type, whether serpentine, V-belts, or timing belts, has specific tension and alignment requirements. Deviating from these instructions can lead to premature wear or malfunction. Similarly, neglecting to thoroughly inspect pulleys and tensioners before installation is another frequent oversight. Pulleys should be aligned perfectly to prevent irregular tension that can cause slippage or uneven belt wear. Furthermore, avoid the common habit of reusing old tensioners or pulleys, which may be worn and lead to inefficacy even with a new belt.

Another frequent error is improper tensioning. A belt that’s too tight can put undue stress on bearings and other components, while a slack belt can impair function and cause noise. Ensuring the correct tension is critical, which may require specialized tools like a tension gauge. Additionally, mishandling the belt during installation—such as bending or twisting unnecessarily—can compromise its integrity, leading to cracks or stretching. Ensure careful handling and support the belt distributing the load evenly during installation.

Maintenance Tips for Longevity

Achieving prolonged belt life necessitates regular maintenance and adherence to best practices. Firstly, consistent visual inspections are vital. Look for signs of wear such as fraying, glazing, or cracking. Addressing minor issues promptly can prevent more significant complications later. Cleaning is equally crucial; belts and their surroundings should be free from dirt and debris that could incite belt slippage or abrasion. Selecting the right cleaning agents that do not degrade belt material is essential.

Regular tension checks should be part of your maintenance routine. Tension naturally loosens over time due to operational stress, and maintaining the correct tension can prevent excess wear or slipping. It’s also advisable to keep detailed records of replacement schedules and any adjustments made, which facilitates proactive maintenance and early detection of recurring issues.

Another tip involves using high-quality replacement parts. OEM (Original Equipment Manufacturer) parts are typically recommended to ensure compatibility and performance. While aftermarket parts may seem cost-effective, they can sometimes compromise reliability and longevity. Lastly, it might sound simplistic, but labeling component positions during disassembly ensures correct reassembly, maintaining the system’s balance and efficiency.

Troubleshooting Post-Replacement Issues

Sometimes, even after a meticulous belt replacement, issues can persist or arise anew. A common post-replacement issue is unusual noise, which frequently indicates improper tension. A squealing sound could suggest the belt is too loose, requiring immediate adjustment. Conversely, a slapping or thumping noise might indicate a too-tight belt or misaligned pulley system.

If performance issues are noted post-replacement, such as reduced efficiency or overheating, a more comprehensive examination may be required. Reevaluate the alignment, ensuring pulleys and belts run in the same plane. One often overlooked solution is checking the load; excessive load can strain even a newly installed belt beyond its limits.

Vibrations or oscillations post-installation might suggest uneven wear during previous operations, demanding a full inspection of associated components. In situations where troubleshooting proves perplexing, consulting a professional with advanced diagnostic tools may be the best course of action. They can provide precise adjustments or recommend specific replacements to alleviate persistent problems.

Implementing these expert tips and practices not only reinforces the belt replacement process but also lengthens the lifespan of belts, achieving both stable performance and reduced maintenance costs over time.

In conclusion, mastering the art of belt replacement is a pivotal skill for anyone responsible for maintaining the efficiency and longevity of machinery. Understanding the fundamentals of belt types and recognizing the signs of wear allows for timely interventions that prevent machinery downtime and costly repairs. Equipped with the right tools and preparation techniques, one can navigate the intricacies of belt replacement with confidence. Adherence to a structured, step-by-step installation process ensures that each phase, from removal to installation, is conducted smoothly and without incident. Safety remains a paramount concern, and following recommended precautions not only protects the installer but also safeguards the integrity of the equipment.

Expert insights into common pitfalls provide valuable foresight, enabling one to steer clear of frequent mistakes and enhance the replacement process’s efficiency. Furthermore, maintaining the new belts with proper care can significantly elevate their performance and extend their usable life, offering substantial returns on investment in terms of time and resources. Should issues arise post-replacement, a systematic approach to troubleshooting empowers operators to diagnose and resolve problems swiftly, restoring machinery to its optimal condition. By integrating these comprehensive strategies, the often daunting task of belt replacement becomes a seamless and rewarding experience, underscoring the importance of proactive maintenance in machinery management.